Cable Counterbalance Spring Balancer Intro:

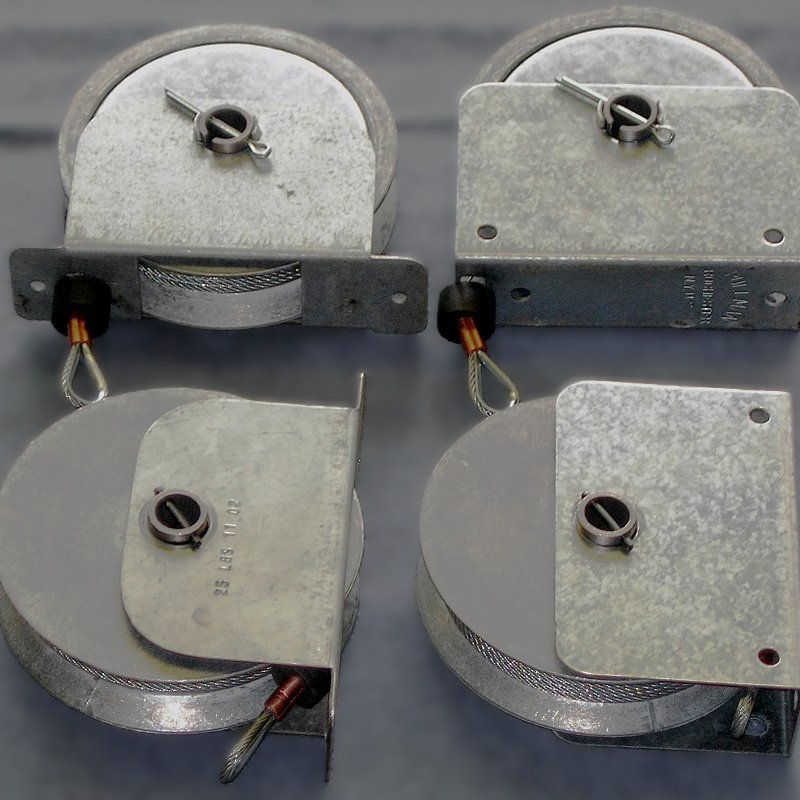

Common names for industrial counterbalances: Tool balancers, tool retractors, cable counterbalances, tensioners, spring balancers, and cable pulleys.

Industrial SPRING counterbalances play a crucial role in various applications by providing a counteracting force to maintain balance and improve efficiency. This white paper explores this specific technology, its function, and key points for selecting the right counterbalance for your specific needs. The advantages of using spring counterbalances and real-world examples of their applications are noted.

What are Industrial Counterbalances?

An industrial counterbalance is a weight or spring-loaded mechanism that creates an opposing force to offset the weight of another object. This helps to achieve equilibrium within a system, preventing unwanted movement or strain.

Applications for Spring Balancers:

Counterbalances are used extensively in various industrial settings, including:

- Tool Balancers: These utilize load capacity and spring tension to suspend tools in a designated location, improving ergonomics and reducing operator fatigue.

- Assembly Lines: Counterbalances can be incorporated into robots or other automation equipment to offset the weight of fixtures or components, ensuring smooth and precise movement. Spring Balances function by reducing strain on workers by counterbalancing the weight of the tool, making them ideal for applications like automotive assembly lines, welding operations, and other tasks requiring repetitive hand tool use, thus improving ergonomics and workplace safety.

- Machinery: In various machinery, counterbalances are used to balance moving parts, reducing vibration and wear on components. The spring balance can support a lid, or countertop, or any moving equipment. The counterbalancing system counteracts the weight and balances the system to achieve the desired result.

- Doors and Lifts: Counterbalances help to offset the weight of heavy doors or platforms, making them easier to open and close.

Real World Examples:

Manufacturing Assembly Lines: Tool balancers with counterbalances are used to suspend heavy welding guns or large components, allowing workers to effortlessly maneuver them during assembly.

Equipment Doors: Counterbalances are integrated into the equipment supporting the movement of heavy doors or access points ensuring precise and controlled movements.

Band Saw (replacement for balancer). The balances can be used for replacement equipment to support band saws and other machines which have a broken counterbalance.

OEM Equipment: Counter balance is often used to support movement of heavy moveable parts in a piece of equipment.

Advantages of Spring Balancers:

- PRICE for weight lifted is lower with spring counterbalances vs other counterbalancing technologies. This is a key advantage.

- Multiple weight options are available and can be viewed on Technical Data Page for Industrial Balancer Reels.

- Eliminate the need to lift heavy tools

- Reduce static loads on the shoulder from constantly holding tools (even lightweight ones)

- Improved Ergonomics: Tool balancers with counterbalances reduce operator fatigue by eliminating the need to hold heavy tools constantly.

- Enhanced Safety: Counterbalances prevent equipment from tilting or moving unexpectedly, minimizing safety risks.

- Increased Efficiency: Spring balanced systems operate smoother and require less power, leading to improved efficiency and productivity.

- Reduced Wear and Tear: Balanced systems experience less stress on components, leading to a longer lifespan and reduced maintenance costs.

- Spring Counterbalances utilize a compressed spring to generate the counteracting force. This allows the balancer to be more compact and fit into existing equipment or on existing production lines.

- Multiple attachment options can be used to fit into the current line, or equipment design.

Key Points:

- Tool balancers utilize load capacity as well as spring tension along a cable to suspend tools in predetermined locations. This is different from a tool retractor that returns the tool to the original position.

- Load Capacity: The counterbalance needs to be able to effectively offset the weight of the object being balanced.

- Work Area: Consider the available space and choose a counterbalance that fits comfortably within your workspace. Dimensions on specification sheet.

- Adjustment Options: Some counterbalances offer adjustability, which can be beneficial for situations where the weight being balanced might vary. Video on website shows how to adjust the balance within 1-2 lb increments.

- The industrial balancer is free floating and supports the proper weight only in the last 30” of the cable length. A locking mechanism is recommended for safety if holding above 30” functional area.

Conclusion:

Industrial counterbalances offer a simple, low cost, yet powerful solution for maintaining balance and improving efficiency across numerous applications. By understanding the different types, benefits, and considerations for selecting a counterbalance, you can optimize your operations and achieve greater productivity and safety in your industrial environment.