Pullman Industrial Tool Balancer and Product Balancer Reels

Pullman Industrial Balancers are built to last with heavy duty retractable steel cable reels and machine casing. They enhance the manufacturing environment by:

- Minimizing operator fatigue on repetitive operations.

- Protecting product or tooling from damage and from dropping.

- Requiring no electricity (powered by Pullman Spring Power).

We can provide custom counterbalances that conform to your exact requirements.

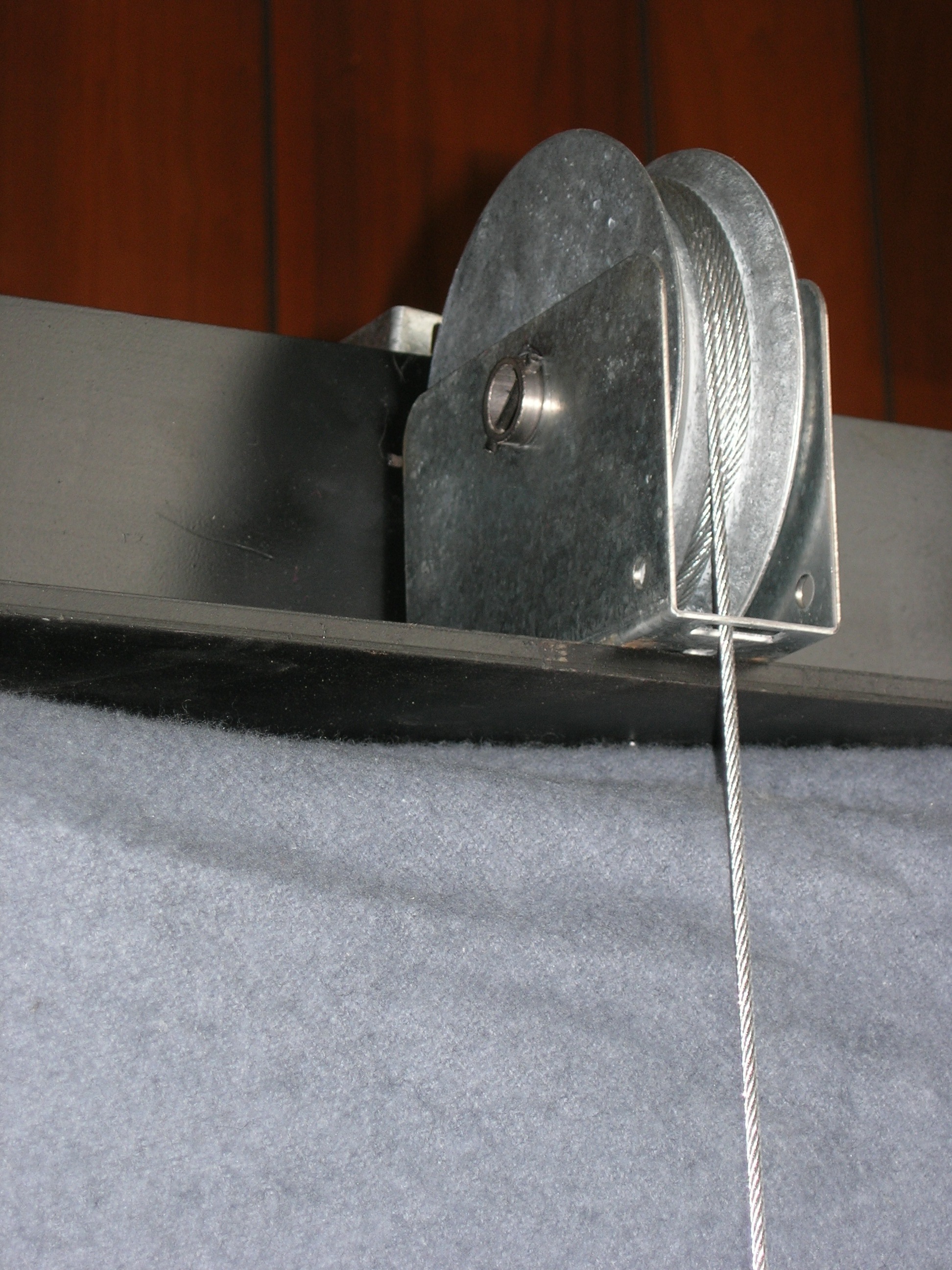

(Click to enlarge)

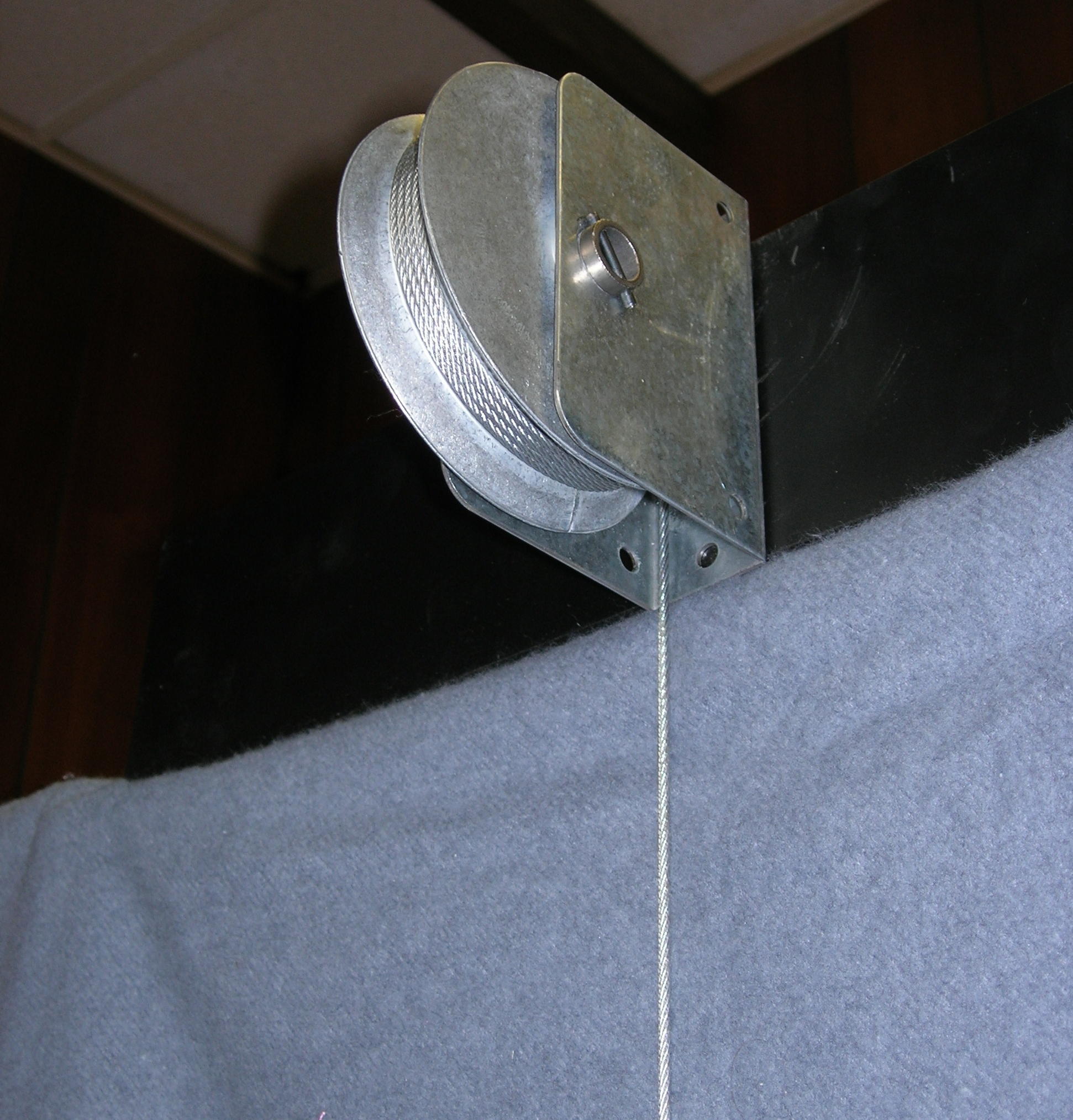

(Click to enlarge)

(Click to enlarge)

Vertical Counterbalancing Applications

- Tool Balancer

- Product Balancer

- Hinged Panels and Lids

- Pull Down Lighting

- Fixtures

- Bulletin Boards

- Industrial Equipment

- Handling Heavy Product during Assembly

- Operations

- Manufacturing Line

- Hospital Equipment

- Safety Guards

- Kiosks

- Panel Saw Return Mechanism

Weights

Pullman Industrial Tool Balancer is available from 3 to 35 lbs. The balance is ordered to a specific weight and is adjustable +/- 1lb. For example, a 10 pound balance can be adjusted between 9 and 11 lbs. (See adjustment instructions and video below).

Weights are determined via a dead weight test and are based on one balance. Multiple balances can be used for heavier weights.

Cable Length and Spring Force

For vertical counterbalancing (door, fume hood, tool balancing, etc.) where the retractable steel cable is preferable to steel tape, the cable may be as long as 96″, but only the last approximately 30″ is accurately counterbalanced for the spring force desired.

Typically the less the spring force or weight involved the greater the distance beyond 30″ is available at the end of the cable extension.

NOTE: the cable length affects spring force, so the exact cable length and the spring load requirement are needed at time of order.

Spring Tension Adjustment

Final adjustment, if necessary, can be easily made in your shop or in the field. To adjust tension: (for cable balance reels only)

- Use a “C” clamp on housing to hold tension.

- Insert any appropriate tool in hole of axle and hold.

- Remove large cotter pin form other end of axle.

- Turn axle clockwise for less tension. Turn axle counter-clockwise (note more than 1/2 to 1 full turn) for more tension.

- Replace cotter pin.

Variable Load Counterbalancing

For overhead doors, hinged panels and lids, the maximum spring force is only needed for a short distance when the object is initially started upward. As the load changes, the spring force lessens, for perfect balancing throughout the cable retraction.

NOTE: For many applications, our tape type clock spring counterbalances are a better solution to normal vertical balancing problems where infrequent cycling and holding the object to be counterbalanced at any position are the objectives.

Multiple Mounting Options

“A” & “B” Styles Available. Click HERE for Industrial Counterbalance Specifications